Make your own sunscreen with ingredients aimed at achieving SPF 50 protection, more reliably than many commercial alternatives. This natural formula combines zinc oxide for its broad-spectrum defense against UVA and UVB rays, with olive oil, coconut oil, and beeswax for a skin-friendly and reef-safe blend. While exact SPF values are hard to guarantee, this DIY approach puts you in control of using trusted, non-toxic ingredients, offering a promising route to safer, high-SPF sun care.

Problems with Commercial Sunscreens

Finding a good sunscreen is challenging. Many store-bought sunscreens don’t work as advertised. Consumer Reports and EWG (Environmental Working Group) each found significant lower SPF’s than the manufactures’ post on their products. Unfortunately, manufactures do their own SPF testing without oversite.

In addition the FDA limits the amount of zinc that can be used in a commercial sunscreen. Making your own homemade sunscreen allows you create a higher SPF, broadband, reef friendly mineral sunscreen from ingredients you trust.

Some commercial sunscreens also use an additional inactive ingredient, trolamine salicylate, that reduces the reddening of the skin. While it has yet to be shown to protect the skin from UV damage, it does allow sunscreens to be rated a higher SPF.

Jump to Homemade Sunscreen Recipe. Or read a post about our favorite commercial sunscreens.

Zinc Oxide, Olive Oil, Coconut Oil and Beeswax

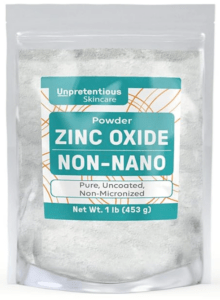

Only one common active ingredient for sunscreen blocks high amounts of both UVA and UVB light and doesn’t contain toxic chemicals that our bodies absorb through our skin, zinc oxide. Titanium oxide does an excellent job of blocking UVB but not UVA (over 90% of the light hitting our skin is UVA).

Almost all the non-oxide sunblocks and many sunscreens with zinc oxide or titanium oxide have additional problematic inactive ingredients. Luckily it is possible to make a simple non-toxic DIY sunscreen with trusted ingredients (olive oil, coconut oil, beeswax, and zinc oxide) and a high SPF.

The best manufactured sunscreens use 25% zinc oxide and some add 7.5% titanium oxide in addition. Titanium oxide is better at blocking UVB (approximately 60% by weight) but it is much worse at blocking UVA light. Many manufactured sunscreens claim to be SPF 50 with the only active ingredient of 20% zinc oxide – this appears to be highly unlikely and probably the reason Consumer Reports is so down on “natural” oxide sunscreens.

Avoiding Other Active Ingredients

Titanium and zinc oxide are the only safe and effective active ingredients recognized by the FDA. While the FDA hasn’t commented on the rest, other research has shown problems with many of the non-mineral active ingredients in sunscreen. Some of them like oxybenzone are hormone-disrupting, have carcinogenic effects and are not recommended for use on children. These chemical are absorbed through the skin into the bloodstream while mineral based sunscreens (zinc and titanium) are not absorbed through the skin.

Many manufactured sunscreens claim to be SPF 50 with the only active ingredient of 20% zinc oxide – this appears to be highly unlikely and probably the reason Consumer Reports is so down on “natural” oxide sunscreens.

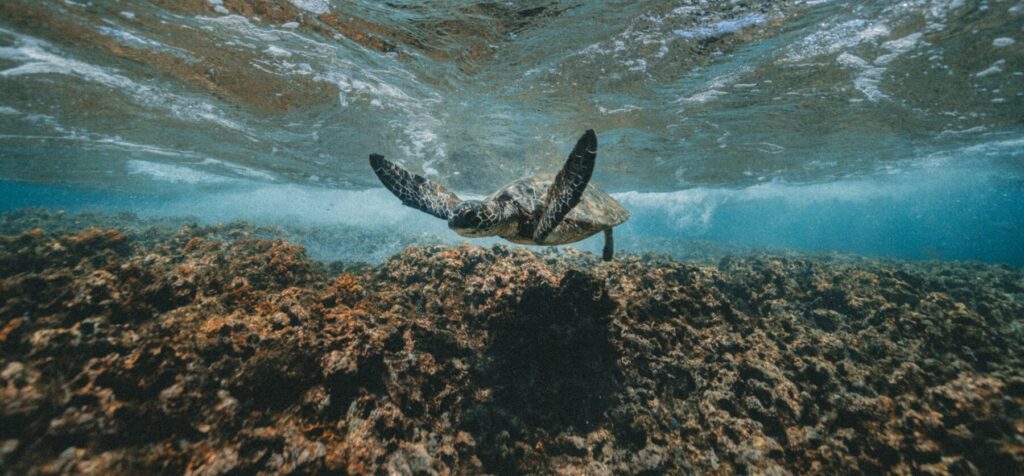

Reef Safe Sunscreen

The only “reef safe” sunscreens are made with non-nano zinc and non-nano titanium. While, sunscreens like SunBum claim to be reef safe, their non-mineral active ingredients are harmful. In SunBum’s case, octocrylene 10.00% is a know problem. Another chemical, oxybenzone, causes the activation of ordinarily dormant virus that lead to the bleaching of corals. Nano (very small) zinc and titanium particles are also toxic to coral.

Hawaii has banned many reef harming sunscreen ingredients including avobenzone, octocrylene, oxybenzone, octinoxate. nano-zinc (really small zinc), and nano-titanium. Alternatively, mineral based sunscreens (zinc and titanium) are believed to be less likely to rub off in the water and the particles are large enough to not be absorbed by the coral.

How Strong is Homemade Sunscreen

While it is difficult to calculate exactly how strong homemade sunscreen is, you can approximate based upon the weight of zinc oxide used to get idea. In general for every 1% of total weight within the sunscreen, zinc oxide provides a SPF of 1.6.

If a sunscreen is 10% zinc oxide by weight than it has an SPF of around 16. Ideally the percent weight of zinc oxide in sunscreen is between 20% and 32% to have an SPF in the 30 to 50 range. (***This idea that 1% zinc oxide gives 1.6 SPF and 1% titanium oxide provides 2.6 SPF is all over the internet but I could not find any scientific support for this claim.)

The FDA limits commercial sunscreens to have no more than 25% zinc oxide and/or 25% titanium oxide meaning homemade sunscreens can have more zinc. If you are concerned about safety of so much zinc, diaper ointment can be 40% zinc oxide.

Homemade Sunscreen Ingredients

| Ingredient | Quanity | Link to Product |

|---|---|---|

| Olive Oil | 1/2 Cup |  |

| Coconut Oil | 1/4 Cup |  |

| Beeswax | 1/2 Cup |  |

| Non-nano Zinc Oxide Powder | 10 tablespoons approx = 3 oz ***oz/tbls varies greatly |  |

Homemade Sunscreen Recipe Directions

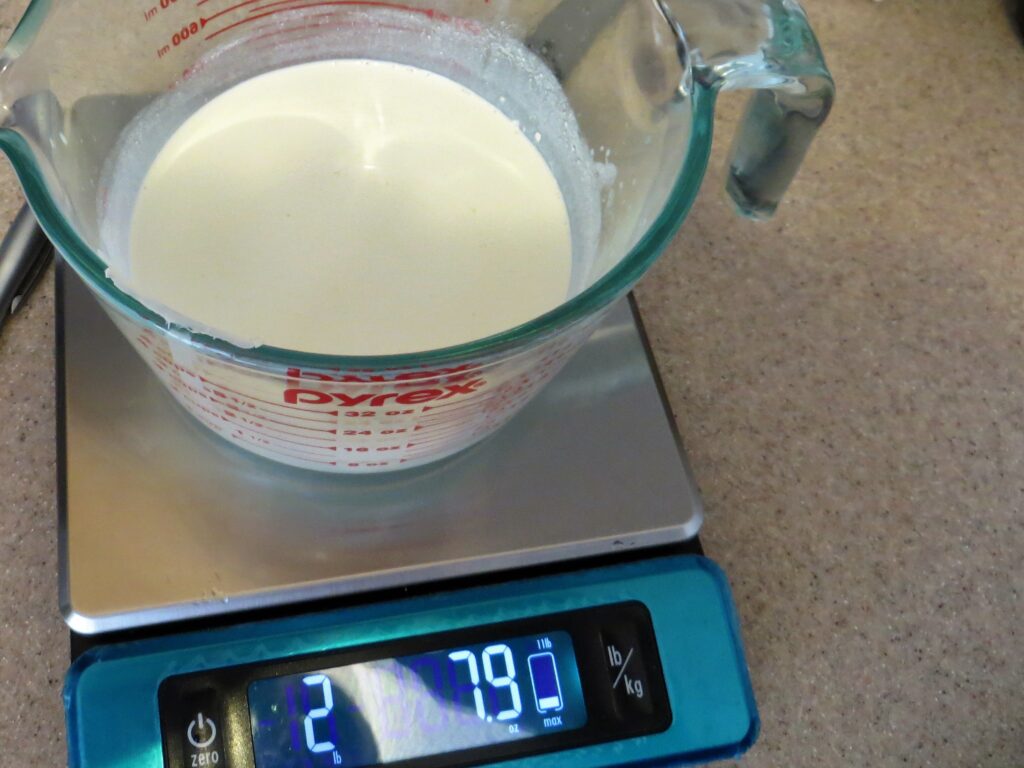

- Weigh container for sunscreen

- Combine ingredients except zinc oxide in a heatable container.

- (Weight materials without zinc + container).

- Add desired zinc oxide, measuring zinc by tablespoon is inaccurate, using a scale is the way to go. Do not inhale zinc oxide, it is toxic for the lungs. (Weight after adding zinc)

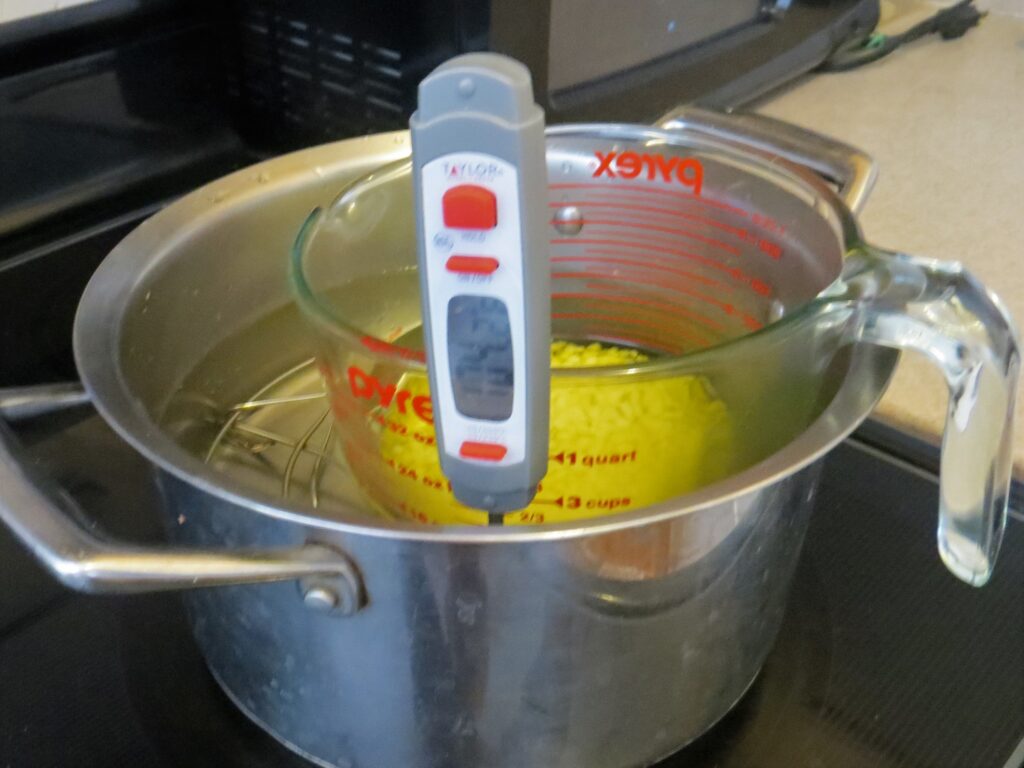

- Fill a pot with a couple inches of water and place on the stove over medium heat.

- Put a lid loosely on the jar and place it in the pan with the water.

Bees wax melting temp = 145 F, discoloration > 185 F

- Put a lid loosely on the jar and place it in the pan with the water.

- Mix the ingredients by stirring as they melt. Watch temperature to avoid discoloration.

- Allow to cool just a bit and then pour into planned storage container. The sunscreen seems to have a better consistency if it is not moved while cooling. You can always later use a knife or spoon to scoop out sunscreen to put in smaller container (even works for chapstick containers but is softer than chapstick).

Calculating % Weight of Zinc

% wt of zinc = (ounces of zinc/total ounces of sunscreen) * 100%

total ounces of sunscreen = (weight after adding zinc) – (weight of container)

ounces of zinc = (weight after adding zinc) – (weight materials without zinc + container)

NOTES

- This sunscreen will make your face white and is a little messy as it will rub off.

- This sunscreen resists water well but still needs to be reapplied after sweating or swimming.

- Make sure not to inhale the zinc oxide. Consider using a mask.

- Add more beeswax to make thicker sunscreen, less to make smooth sunscreen.

- Store in a cool, dry place or in the fridge.

Concluding Thoughts on Homemade Sunscreen

This is just one recipe for sunscreen. In the past I’ve enjoyed using homemade sunscreens with shea butter which makes the sunscreen a little stickier. This recipe works well in the water as long as it is not rubbed. For example where a shirt rubs at the wrist it will remove the sunscreen. My wife loves the texture of this recipe. We use it for our daughters rashes and when her nose is raw during a cold.

Comments about other versions you’ve made would be greatly appreciated!